Autoclaved Aerated Concrete (AAC) is a siliceous material (sand, fly ash,gangue etc.) and calcareous materials (lime, cement) as the main raw material, mixing with foaming agent(aluminum powder) by mixing, casting, pre-curing, cutting, autoclave process made of light weight concrete products.

As a result of its excellent properties, AAC is used in many building constructions.

AAC Plant Mould

Main features:

Mold is a necessary equipment for the production of aerated concrete and can be put into use.Combined with the side plate, the mold can hold the slurry, and then stand curing and foaming to solidify into the embryo body. At the same time, the side plate carries the embryo body to the cutting machine for cutting, and then it is assembled with the steaming car and then enters into the autoclaved kettle for steaming and raising.

![]()

Advantage:

The mould is composed of two main parts, the frame and the bottom plate of the mould. The mould is an important equipment for shaping the finished product. The mould produced by our company has the advantages of good rigidity, simple structure and no leakage of pulp.

![]()

Structure:

Mold bottom plate: the four sides are welded with square steel structure. The upper layer of 8mm thick steel plate strengthens the rigidity to prevent deformation and damage to the blank body.

Mold frame: there are two kinds of movable type and integral type.Double-layer hollow side plate ACTS as insulation, and the inner plate is welded with 10mm thick steel plate to increase its rigidity, prevent deformation and prolong the service life.

Fixed die frame, the upper mouth is slightly smaller than the lower mouth, so as to facilitate stripping.Good rigidity of mould frame, easy to demoulding, no leakage of pulp, and has good interchangeability.

The bottom plate is made of special rectangular steel tube, channel steel and steel plate.Baseplate not only durable, good stiffness, not easy to deformation, but also need to have good interchangeability.

Brief introduction of SANKON Company.

History:Sankon Building Materials Technology CO.,LTD are professional building materials machinery and equipment research, manufacture and export company. Company business started from 2004, now our workers, sales and service branch staff are more than 200 people. Whole company year turnover is more than 50million USD. The company's main products are AAC block making machinery, concrete block making machine, concrete pole pipe making machine, concrete roof tile machine and mixers.

Products:The company passed ISO9001 management system and the European Union CE certification, the products absorb the German mechanical design and manufacturing experience, focus on quality design, high quality material, exquisite welding and strict inspection process to ensure high quality equipment and maximize service life. Company products are exported to Southeast Asia, Africa, South America, Eastern Europe, the Middle East, Australia and more than 100 countries and regions.

Spirit:To be persistent and innovative; To achieve an excellent and perfect SANKON.

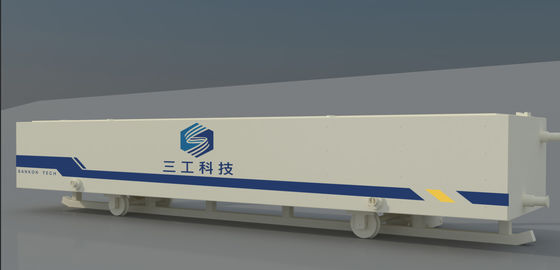

Packing & Shipping:

Package conforms to the requirements of customs.

After-sales service:

1.Provide engineers abroad installation and commissioning service.

2.Held online or site training for workers to ensure the safe operation.

3.Our expert will answer any inquiry within 24-48 hours and it will be solved as soon as possible.

4.We supplies the complete technical documents and the relative drawings of the electric components which were written in Chinese and English.

5.Service is available lifelong.